Last month we traced the history of Thwaite Watermill in Stourton from its origins up until 1871. Now we bring the story up date.

The year 1872 saw the Horn family arrive at Thwaite Mill, taking on the tenancy for £100 per annum thus showing the poor state of the property at this time. Stone crushing machinery was installed by the Horn family so that the mill could be used for grinding flint, china stone, and chalk, and at the same time they renovated the existing machinery. Sadly, however, Thomas Horn’s 15 year old son was killed while replacing the large water wheel.

Raw materials for crushing arrived by barge and from 1920 were transported on a small railway known as the Jubilee Line to the mill buildings. China Stone was sourced from the Cornish Coast, while flint came from Kent, and chalk came from the Hessle Quarry in Yorkshire. Most finished materials left the mill in the same way as they arrived.

Flint and china stone were ground together to make a final slurry which was used to make glaze (the shiny surface on ceramics) for local potteries like those at Castleford and Ferrybridge and were transported in barrels by horse and cart, but for further afield the slurry was pumped from huge underground tanks into specially modified barges. The First World War however saw the end of the Aire valley pottery industry and the result put an end to the grinding of flint and china stone.

Chalk was also ground at the mill where it was broken down into egg-sized pieces by a jaw-crusher. It was then fed into a water-filled edge runner, known as the Tommy Mill, to be crushed into slurry. This was fed into a water levigation system where it was separated into three grades using buoyancy. The bigger heavier pieces sank to the bottom of the first pit and so on until the final pit contained chalk with the consistency of soft butter which was known as Paris White and air-dried in the form of ‘cakes’ on racks in the mill attic.

Slurry from the lower pits was transported into the drying sheds each shed having four furnaces which heated flues under the firebrick floor the slurry was poured over to a depth of 5 or 6 inches and left for two days until dry.

The chalk powder or ‘whiting’ was then bagged and sent off to be used in all sorts of products, from paint to toothpaste and other pharmaceutical items. Records even show that a monthly consignment was sent to Wakefield Prison to go into inmates’ bread.

In 1923 the Horns began producing putty as a way of using up surplus whiting which was mixed with Canadian linseed oil in the ratio of one part oil to seven parts whiting and this became their most successful venture and becoming their only output by the 1960s.

Their success was due partly to them installing a Raymond Mill in 1931, which increased output and efficiency; this machine was originally developed to crush coal. A Marshall Diesel engine was brought in to power the Raymond Mill because the wheels weren’t strong enough although they were still used for mixing the chalk and linseed oil.

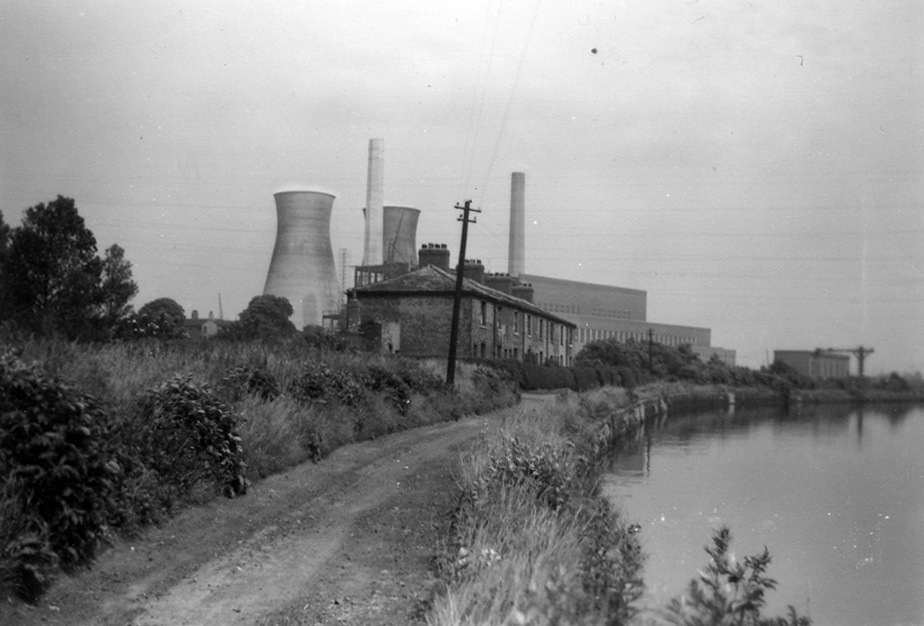

During the time of the Horns management there were a variety of jobs for the workers at the mill and for the first few decades, during the Victorian era, employment was available at Thwaite House as well. Lots of Horns’ employees lived in Dandy Row; the set of eight cottages located nearby along the Navigation and built in the 1820s, possibly with bricks from the old buildings in Briggate. These cottages were pulled down in 1968 to widen the Navigation.

Following the Second World War Thwaite Mill continued to be successful, putty production in 1950 was estimated at 800 tons per annum. Another feature to be replaced at this time was the wooden swing bridge built in 1824 this had been operated by the ‘penny-man’, who allowed tall-masted keels, sloops, and other vessels to pass in return for a small toll.

These pennies accounted for his entire wage, and if no boats were passing he spent his rime in his little wooden hut doing odd jobs such as cobbling shoes. The job of the penny-man ceased because the bridge became too rickety for use and in 1951 a new one was built of concrete.

The success of Thwaite Mill was not to last and as time progressed the Horns’ production methods became outdated and they were less able to compete with newer manufacturers and with the market now changing to uPVC window frames and double glazing they decided to close the mill. The final nail in the coffin was on the night of the 29 January 1975 when the river breeched the weir causing it to collapse thus preventing water from being diverted into the mill and turning the wheels.

Fortunately the mill was not left empty for long and in 1978 the Thwaite Mill Society was formed from a group of volunteers who did not want to see the site go to waste. The weir was rebuilt, the buildings and water wheel were repaired and refurbished and in 1990 the site reopened as a working Museum run by Leeds City Council.

However, in 2024 this now seems in doubt. The Council are said to be pulling out of a deal struck between them and the Canal & River Trust who will be left in sole charge. Does this mean another South Leeds heritage asset disappearing?

Main photo: Loading putty at Thwaite Watermill

While you’re here, can we ask a favour?

South Leeds Life is published by a not-for-profit social enterprise. We keep our costs as low as possible but we’ve been hit by increases in the print costs for our monthly newspaper which have doubled in the last two years.

Could you help support local community news by making a one off donation, or even better taking out a supporters subscription?

Donate here, or sign up for a subscription at bit.ly/SLLsubscribe

Thank you Ken Burton for taking the time to research and to write the history of this mill , I’ve visited it several times in the past, it would be a shame if it has to close down in the future, I hope this doesn’t happen and it remains open to future visitors