John Blenkinsop was a Mining Engineer and Steam Locomotive designer who was born at Felling, near Gateshead, County Durham.

When he was old enough he was apprenticed to his cousin, John Straker, the Coal Viewer for Charles John Brandling’s Felling Colliery. Brandling lived at Tilling, County Durham; and he married Henrietta Armitage an heiress of Middleton near Rothwell who was the grand-daughter of Sir Ferdinand Leigh of Middleton.

On 1 October 1808 Blenkinsop was appointed Agent for Brandling’s Middleton Pits at a salary of £400, five times what other experienced colliery workers earned. At the time of his appointment the Middleton Pits were ‘capable of great improvement’ and this was Blenkinsop’s main task.

From then until his death in 1831 he lived at Middleton Hall on Town Street, Middleton. In addition to managing the Middleton collieries Blenkinsop was also the Consulting Engineer for Sir John Lister Kaye of Denby Grange, owner of Caphouse Colliery. In the 1820s he was hired by other Colliery owners, also as a Viewer, to examine their collieries and report on such vital matters as to expected future production and to make suggestions how the operation and production could be improved.

In 1758 the Middleton Tramway was built to carry coal to Leeds and the River Aire for shipment. This was the first railway to be authorised by an Act of Parliament in 1758 and had a gauge (width) of 4 feet 1 inch. Not all the land that the railway crossed was owned by Brandling but the Act gave him power to obtain way-leave. The operation was privately financed and operated using a tramway with wooden rails and horse-drawn wagons. In about 1807 the wooden track began to be replaced by metal edge-rails.

During the Peninsular War of 1808 to 1814 the Duke of Wellington’s Army in Spain and Portugal required a huge amount of fodder and this caused a dramatic rise in the cost which in turn led to an increase in the cost of horse transport in Britain. Blenkinsop thought of other ways to move the coal, a canal was not an option due to the hilly nature of the pits’ location, other steam locomotives were far too heavy and breaking the iron rails. He came up with the idea of making the locomotive as light as possible although he worried there would be problems on a gradient.

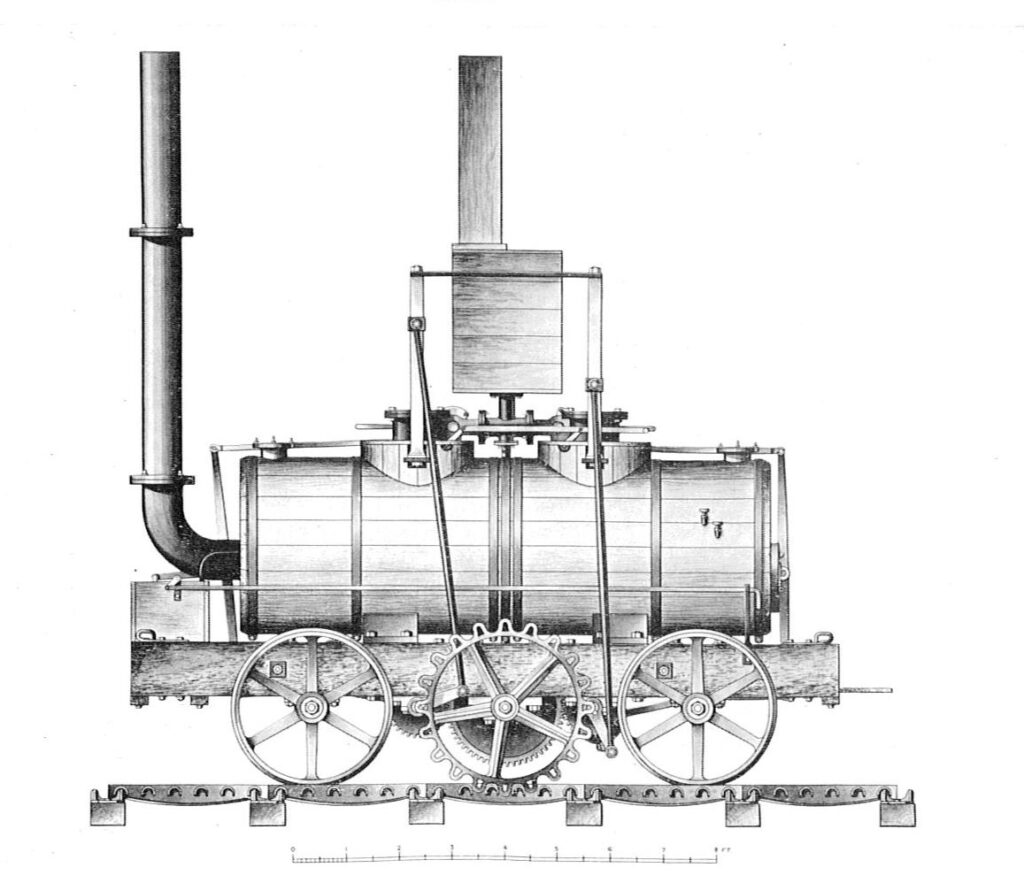

His solution was to use a rack and pinion system (his Patent GB 3431 of 1811) using a cog or pinion on the engine and a rack attached to the rails. He placed the execution of his design in the hands of Fenton, Murray & Wood at their Round Foundry, in Holbeck who at that time were an eminent firm of Mechanical Engineers in Leeds (Matthew Murray is said to be the Father of Leeds Engineering).

This was the first locomotive in which two cylinders were employed, a great improvement on earlier attempts by Trevithick and others. The cylinders were placed vertically and were immersed for more than half their length in the steam space of the boiler, using this system also did away with the need for an external flywheel.

The boiler was made of cast-iron and was of the plain cylindrical type with one flue – the fire being at one end and the chimney at the other. This assembly was supported on a carrier without springs, directly on two pairs of wheels and axles which were unconnected with the working parts of the engine serving primarily to carry the engine on the rails the progress of the engine along the rails was by a cogwheel working on a toothed rack cast on the side of one of the rails. While the locomotive was made at the Round Foundry, Holbeck, the rails were cast at the Hunslet Forge.

Blenkinsop managed to persuade the colliery owners to invest in this new system and an engine was made and set to work on 24 June 1812. It weighed five tons and could haul 90 tons at 4 mph on a level track. A second engine named Salamanca after a recent British victory in Spain was introduced at the official opening on 12 August 1812 from the Middleton Colliery to Casson Close, Hunslet Lane a distance of about 3½ miles. This was some two years before George Stephenson started his earliest locomotive and was undoubtedly the first commercially successful steam locomotive employed on any railway.

In 1816 the Grand Duke Nicholas (afterwards Emperor of Russia) observed and was impressed by the workings of the locomotive as it dragged behind it as many as 30 coal waggons at a speed of about 3¼ mph. Three other locomotives were built later and remained in service for another 20 years.

On 28 February 1817 Salamanca blew up killing the driver and scalding several children, the driver having tampered with safety valve to prevent it from working at a time when the engine was not in motion.

Similar locomotives were built for collieries at Orrell near Wigan by Robert Dalglish under licence from Blenkinsop, and at least one other was built at the Round Foundry for the Kenton and Coxlodge collieries at Newcastle-on-Tyne.

What should have been Blenkinsop’s third locomotive had already been sent to the Kenton and Coxlodge Waggonway at his request and here it seems to have acquired the name Willington. Two locomotives of this pattern were made by the Royal Iron Foundry, Berlin and though they worked well at the foundry when tested neither could be made to work properly at their intended workplaces and ended their days as stationary engines.

In 1825 Blenkinsop was one of the first rescuers to enter Middleton’s Gosforth Pit after an explosion of firedamp, this is possibly an contributary factor to his death at the age of 47. He died on 22 January 1831 in Leeds after a “tedious illness” and was buried at Rothwell Parish Church.

In 1881 the railway was converted to the standard gauge of 4 feet 8½ inches. The locomotives went out of date when malleable iron rails replaced cast iron rails, this meant that heavier engines could be supported on lighter rails and although the rack and pinion system fell out of general use variations of it are still used today on mountain railways.

While you’re here, can we ask a favour?

South Leeds Life is published by a not-for-profit social enterprise. We keep our costs as low as possible but we’ve been hit by increases in the print costs for our monthly newspaper – up 83% in the last 12 months.

Could you help support local community news by making a one off donation, or even better taking out a supporters subscription?

Donate here, or sign up for a subscription at bit.ly/SLLsubscribe