Continuing our series looking at the bridges that cross the River Aire and canals in Leeds, our next bridge down river from Wellington Bridge is Monk Bridge on the Whitehall Road.

This bridge derived its name from an area called Monk Pits, an area of meadowland to the north of the River Aire. A lock known as the Monk Pit Lock along with a small section of canal, the Monk Pit Branch, was built to provide access between the canal basin and wharves above the Bondman Dam.

This dam was built on the River Aire near Mill Hill in the Middle Ages. It controlled the waters to the King’s Mills and was constructed by driving wooden piles into the river bed. A timber frame was then erected with the infill made up of stones, sand, clay and faggots. Maintenance of this dam was essential in view of the economic importance of the mills.

Later the Monk Pit Branch also became very important as a means of providing coal to the power station in Whitehall Road opposite Thirsk Row. This later led the bridge on Whitehall Road taking the name Monk Bridge. It is known that letters appeared in the ‘Leeds Mercury’ putting forward the case for building a bridge by the Monk Pits as early as 1817 and it later became a necessity with the building of the Whitehall Road, the road linking Leeds and Halifax.

On 22 December 1823 the first public meeting was held at Adwalton to discuss the proposed road and Mr Dinsley of Huddersfield in association with Charles Fowler of Leeds were appointed as engineers. Each engineer prepared a separate scheme and these were discussed at a meeting held on 2 February 1824. This led to an application to Parliament and on 25 May 1825 the Act received the Royal Assent.

Contracts were let on 16 November 1825 for the first section from Drighlington to Cleckheaton and on 14 December of the same year two more sections were let from Wyke to White Hall, Halifax. During 1826 the money from subscribers began to run out and a loan of £4,000 was obtained from the Exchequer Loans Committee to enable a start to be made on the major engineering project, the bridge over the River Aire and the Leeds & Liverpool Canal at Monk Pits, Leeds.

On 29 December 1826 contracts were let for a stone bridge with a 30 foot span over the Leeds & Liverpool Canal and for the masonry for an iron suspension bridge with a 112 foot span over the River Aire. The carriageway was to be of 26 feet width with two five foot pavements on either side.

The Civil engineer for Monk Bridge was George Leather of Bradford and was done in the style referred to as a bow string suspension bridge and the cast iron work was by the engineer of Sturges & Company of the Bowling Ironworks, Bradford where the iron components were made.

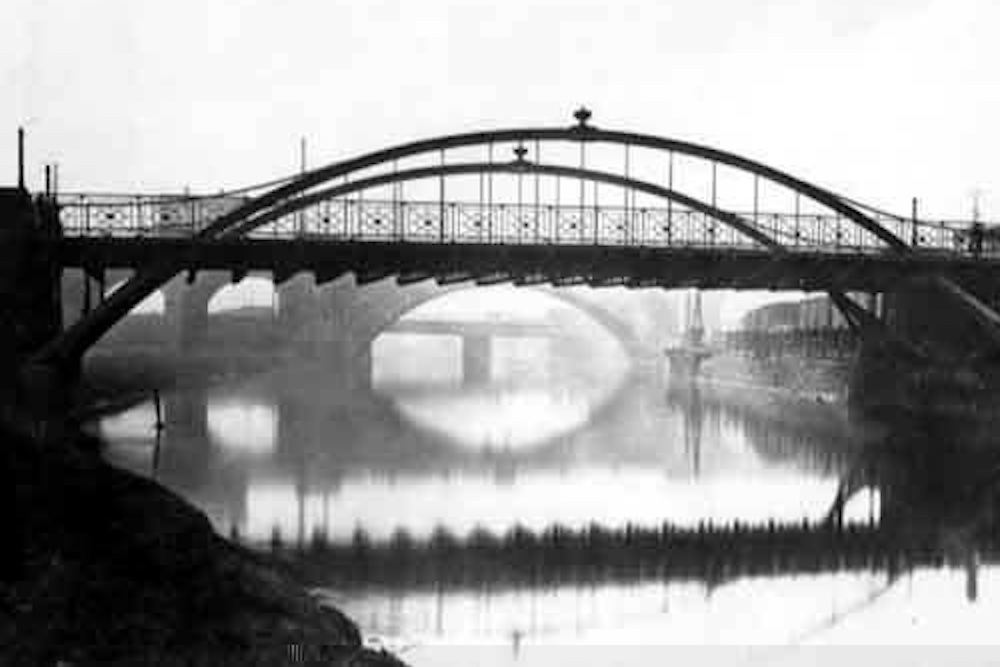

The original bridge consisted of a through arch bridge with a suspended deck spanning the River Aire, an elliptical arch over the canal and two land arches over the footpath. The arches were assembled from iron castings with ball and socket bearings at the springing. The cost of the ironwork for the bridge was £320.6s.0d (£320.30p).

Construction of the bridge took place with no major problems and on 7 November 1827 George Leather carried out a load test and confirmed that the bridge would take a load of 150 tons. Although the bridge was completed it could not be opened because the road links from Wellington Street and Gelderd Road had not been built because the bridge had taken up all the money and it was to remain like this for the next four years.

On Monday 23 April 1832 the barricades were removed from the ends of the approach roads at Wellington Street and Gelderd Road, Monk Bridge and the two roads, Aire Street and Whitehall Road, were opened and the tolls were taken at the same rate as Wellington Bridge.

In 1866 the bridge was purchased by Leeds Corporation from the Trust and in 1883 the bridge was advertised for sale by Leeds Borough and it was obvious that the old bridge was unable to cope with the weight of the increased volume of traffic and that a new bridge would have to be built by Leeds Corporation.

The new bridge was designed by Thomas Hewson the Borough Engineer, and the river span was of iron lattice girder construction, with a span of 109 feet. Rows of cast iron owls lined the parapet and the Leeds Coat of Arms was carved in the stone pillars either side of the bridge. The bridge over the canal was also replaced with a cast iron structure with the Leeds Coat of Arms cast into the ironwork.

The contract amounted to £9,439 and the actual expenditure was £9,557 with a repayment period for the money borrowed was 30 years with an annual charge for principal and interest of £450. The contractors for the masonry were Whitaker Brothers, Horsforth, and for the ironworks, Butler & Sons, Stanningley.

Originally an attempt was made to make the bridge less utilitarian by using owl themed appendages on the top chord and by disguising the lattice structure by overlaying decorative castings having circle/star/rope motifs. The bridge remains basically as built in Thomas Hewson’s time but the owls have long disappeared from the top chord and the Leeds Coat of Arms have now disappeared from the cast iron plates on the canal bridge. The carved Coat of Arms on the stone pillars are rapidly being weatherworn away.

While you’re here, can we ask a favour?

South Leeds Life is published by a not-for-profit social enterprise. We keep our costs as low as possible but we’ve been hit by increases in the print costs for our monthly newspaper which have doubled in the last two years.

Could you help support local community news by making a one off donation, or even better taking out a supporters subscription?

Donate here, or sign up for a subscription at bit.ly/SLLsubscribe