The Hunslet Engine Company was founded in 1864 and the workshops were built on a plot of land on which had been the locomotive works of EB Wilson & Co and named the Railway Foundry.

The buildings had been pulled down and not withstanding the fact that there were already three locomotive builders established around this site (Manning Wardle, Hudswell Clarke, and Kitson) the founder thought there was enough work for another.

John Towlerton Leather, a railway contractor and civil engineer was the founder of the Company which he built for his son, Arthur Leather, hoping that orders could be obtained for contractors and industrial locomotives. John Leather appointed James Campbell as Manager, James was the son of Alexander Campbell who was the Manager of Manning Wardle. Although building the same type of product there was a close relationship between the two firms and Hunslet were assisted in the building of their first locomotives by Manning Wardle supplying materials, the designs of each show a great similarity of main features.

The first locomotive built by Hunslet was a 0-6-0ST (saddle tank) with inside cylinders and the tank over the boiler barrel only, a combined dome and safety valves over the firebox while the cab was a weatherboard bent over a small amount towards the rear. This was completed on 18 July 1865 and supplied to Brassy & Ballard railway and civil engineering contractors working at Ampthill in Bedfordshire and given the name ‘Linden.’

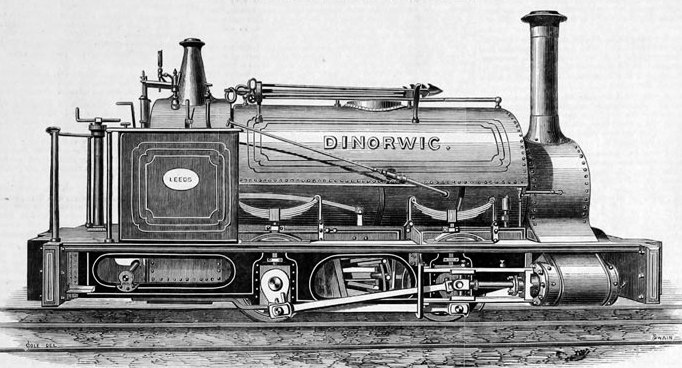

In 1870 Hunslet constructed their first narrow gauge engine “Dinorwic” a 1 foot 10¾ inch gauge 0-4-0 ST for the Dinorwic Slate Quarry at Llamberis. This engine was later renamed “Charlie” was the first of 20 similar engines built for this quarry and did much to establish Hunslet as a major builder of quarry engines. The quarry was linked to Port Dinorwic by a 4-foot gauge line for which Hunslet built three 0-6-0T (tank) engines.

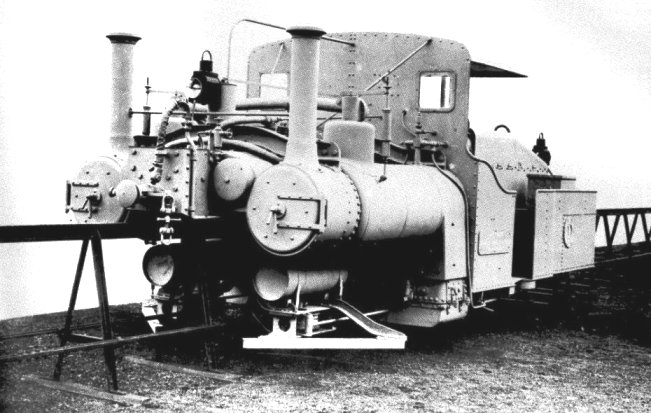

In 1887 three of the most novel locomotives built by Hunslet appeared. They were for the Listowel & Balybunnion Railway for Lartigue’s Patent Monorail. The locomotives had twin boilers of the locomotive type and were suspended on a rail fastened on to trestles. There were three coupled wheels of 2 foot diameter and two cylinders and the tender was also powered by two cylinders driving two wheels of 2 foot diameter through a clutch and shaft. This was an early type of booster but it was not required as the locomotive was capable of all duties required.

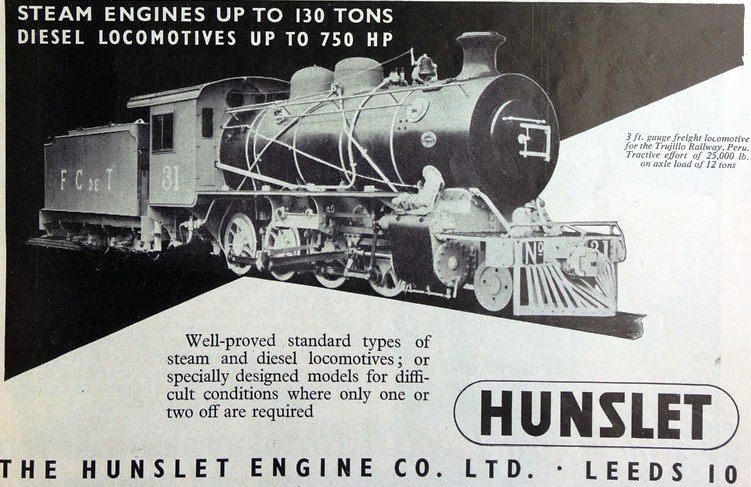

By 1902 Hunslet had supplied over thirty countries world-wide, often opening up new markets. The Company offered their expertise to customers by sending engineers to carry out repairs on their premises, a service that Hunslet was still offering in 2006; they also offered quick build, an order for a new 0-6-0, 3 foot 6 inch gauge locomotive was received on the Saturday 15 April 1901, it required the production of 40 new drawings. The steel frames and boiler were received on 20th, cylinder castings on 22nd. The completed boiler was tested on 30th and the locomotive was completed on 5 May just 20 days after the order was placed. It was stripped down and packed for export on the 8 and 9 May and on the dockside at Liverpool on 10 May.

Arthur Leather was not interested in locomotive matters so in 1871 James Campbell and his brother George Campbell bought the Company for £25,000, payable in five instalments over two years and the firm remained in Campbell ownership for many years. By 1901 James Campbell as the proprietor was still in charge and his four sons were all working for the Company including the eldest son Alexander III who had taken over as Works Manager on the death of his Uncle George in 1890. In 1902 the company reorganised as a Private Limited Company with the name Hunslet Engine Company Limited but still a family business. From 1903 to 1906 a car the ‘Attila’ was produced by the Company, this was a three cylinder vehicle and in 1905 they also built a four ton truck.

Following the death of James Campbell in 1905 the Chairmanship passed to Alexander III and his brother Robert became Works Manager, while brother Will retained the role of Secretary and Traveller with a seat on the Board. Following a family disagreement both Will and the youngest brother Gordon left the Company while a serious works accident left Robert disabled and unable to continue as Works Manager.

In 1912 the post of Works Manager was advertised and Edgar Alcock, who at the time was Assistant Works Manager at the Gorton works of Bayer, Peacock & Company, was the successful applicant. Alcock came to Hunslet at a time of change when the industry was being asked for far larger and more powerful locomotives than had been required in the past. This was true at Hunslet where its overseas customers were asking for very large engines.

However by 1914, Britain was at war and overseas orders had dried up. Hunslet like many other companies started to employ women on the shop floor manufacturing munitions.

After the war trading conditions were very difficult but Hunslet were once more able to attract overseas orders and at the same time they also received a series of repeat orders from the LMS Railway for 90 LMS Fowler Class 3F ‘Jinty’ 0-6-0T shunting engines. In 1927 Manning Wardle & Company (Boyne Works) went into voluntary liquidation, the goodwill of the Company was bought by Kitson & Company while Hunslet bought a portion of Manning Wardle’s works of about five acres which enabled them to extend their workshops at a time when space was badly needed.

In the same year Edgar Adcock’s son John joined the Company and as a result of his father’s insistence he made a special study of the internal combustion engine being applied to railway construction.

1930 witnessed the closure of the Kerr Stuart works in Stoke-on-Trent the goodwill of this Company passing to the Hunslet Engine Company. It was during the 1930s that Hunslet built their largest locomotives, two 0-8-0T engines for a special train ferry loading job in China which they fulfilled for many years. A year or two later the same design formed the basis for an 0-8-0 tender engine for India. The years between the wars was the time many ‘large engine’ orders were received.

A further voluntary liquidation occurred in 1934 when the Avonside Engine Company, Bristol, closed. A year later Hunslet bought the goodwill of the firm together with the drawings and patterns, etc, but they didn’t acquire the premises.

The arrival of World War Two saw orders completed where possible, while a great amount of work was done for the Ministry of Supply such as anti-tank guns, shell cradles, aircraft parts, etc. In the later years of the war two types of locomotive were required by the Ministry for moving vast quantities of goods before and after D-Day. One was a mainline freight and the other a powerful shunting tank engine. The LMS3F was put forward for the latter but eventually it was decided to use a design based on an Hunslet 0-6-0ST which had first appeared in 1937 and a total of 484 of these were built from 1943-1964, 217 of these by Hunslet. In total Hunslet built 2,236 steam locomotives.

During the war the Company built both steam and diesel locomotives for the war effort an this work carried on post-war with increased vigour particularly with the Hunslet flame-proof diesel engines for the mining industry and diesel shunting engines for both home and overseas use.

The Scootacar was a coupe produced by the Company from 1958 to 1965 with about 1,000 being built. In 1972 they purchased Andrew Barclay, Sons & Company and the name of the Company changed to Hunslet-Barclay and in 1979 they bought from the receiver Fairburn & Lawson Group of Leeds bringing textile equipment, machine tools and electric locomotives into the range of products.

In 1982 Hunslet Holdings of Leeds employed almost 1,000 staff and was described as a locomotive and mining equipment manufacturer. The Jack Lane, Hunslet works were closed down in 1995 after the last order for a batch of narrow gauge diesel locomotives for tunnelling on the Jubilee Line Extension on the London Underground had been completed.

The Hunslet Engine Company became part of the LH Group of Companies and continues to trade from a Leeds 10 address and also claims ownership of “the intellectual property and design rights to nine British locomotive names, including the ability to service, repair, and supply genuine replacement components.” The Group later became part of the Wabtech Corporation of Pittsburgh, USA and in 2019 they too merged with GE Transportation also of America

Main photo: Linden was the Hunslet Engine Company’s first locomotive

While you’re here, can we ask a favour?

South Leeds Life is published by a not-for-profit social enterprise. We keep our costs as low as possible but we’ve been hit by increases in the print costs for our monthly newspaper – up 83% in the last 12 months.

Could you help support local community news by making a one off donation, or even better taking out a supporters subscription?

Donate here, or sign up for a subscription at bit.ly/SLLsubscribe