Two young men who were employed in the Engineering Labourites at the Yorkshire College visited a soap works in 1897 where they saw a number of girls wrapping the bars of soap by hand. Andrew Forbes and Frederick Grover thought that a mechanical device could be provided to carry out this necessary but tedious operation and in their spare time they designed and made an automatic machine for this purpose.

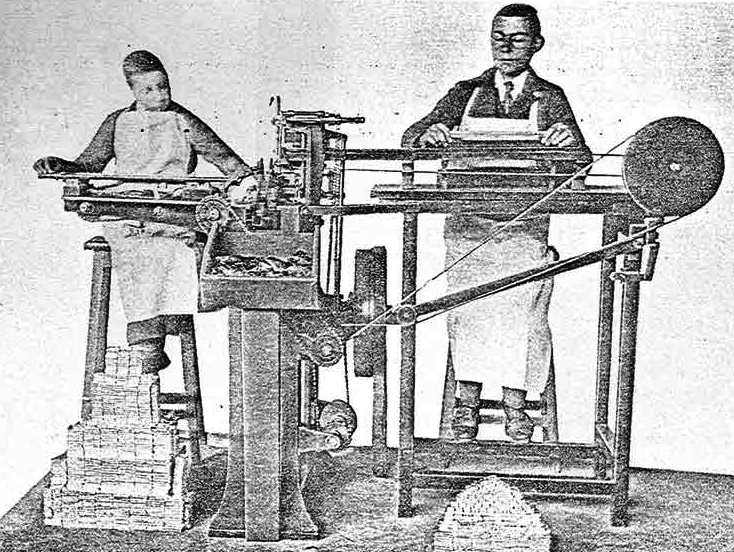

However, it was not a commercial success so they adapted it for wrapping pieces of butterscotch and offered it to Parkinson’s of Doncaster. But once again this was not successful however it was found to work fine on oblong tablets of moulded chocolate. The “Old Rocking Horse” as it became known because of its action could wrap at 100 pieces per minute and was soon being sold to chocolate makers in England and Switzerland.

It was decided by the two men to start a company the name of which was based on their names FOR from Forbes and GROVE from Grover and the result was the Forgrove Machinery Company Ltd. The company was formed on 3 August 1901 with a capital of £1,000 provided by Grover’s relative JW Bennett, the company’s first Chairman.

Production was carried out at the Union Foundry Mills in Dewsbury Road although at this time wrapping machinery was not in general use and at the end of the first year of operation managers reported that five machines had been made and sold and were confident that ten could be produced the following year. The Company beat its own target by producing an average of one a month.

In 1904 the Company moved to larger premises at No.8 Admiral Street further up Dewsbury Road near Moor Road and Hunslet Hall Road junction. In this year Mr Grover became Chairman of the company, a post he held for 35 years, and with the resignation of Mr Forbes at the end of the year, he also became its sole Managing Director. In 1905 a London office was opened in Queen Victoria Street and in 1906 the Admiral Street premises were extended. Headquarters staff consisted of five people and a boy along with 66 works employees.

1907 saw negotiations take place in the USA regarding the right to a Forgrove machine. Subsequently a number were made in America by a company formed and called the Consolidated Wrapping Machine Company in which Baker Perkins’ French associates, Jeanjean had an interest but no lasting development took place as far as Forgrove were concerned.

During the First World War there was a cancellation of orders for wrapping machines and like others Forgrove took to war munitions work with a series of contracts for machining 6-inch shell noses although during the four years of war they also managed to produce 80 wrapping machines and after hostilities finished had a large number enquires.

It was thought that with the capital gained it was in order to extend and to this extent an acre of land was purchased at Oakhurst Avenue, Dewsbury Road and a new works and offices of some 13,000 square feet was built and finished by 1920.

In 1927 Forgrove’s association with Baker Perkins began. This was prompted by the sudden death of Forgrove’s salesman in the USA, Mr McKeage. HG Wenban made a trip to America to preserve continuity and arrange for Baker Perkins Inc to carry on the Agency. In 1928 Forgrove’s arrangements with Baker Perkins were complete with the latter selling Forgrove machines exclusively at home and abroad and also taking a minority holding in Forgrove with a member of Baker Perkins joining the Forgrove Board.

In 1929 the Drawing Office was extended followed in 1930 by a two bay extension to the works and by 1933 three more bays were added to the works to accommodate increasing business. In spite of the previous extensions factory space was still too restricted so in 1936 a major extension involving building a two storey concrete and brick extension on the Company’s original land area to double the factory production area. During this work there was some disagreement over boundaries with the owner of the adjacent property which led Forgrove buying the land and buildings on it.

World War Two was on the cards and the Ministry of Supply was in touch with Forgrove in 1938 asking them to plan for armaments production. When the war began Forgrove employees totalled 313 – 64 staff and 249 workers but by 1941 work was going on round the clock and over 700 people were employed including around 200 women.

The main wartime production was gun sights for 25-pounder guns a large portion of which was sent to the Westwood Works where the guns were assembled. Gun sights were also made for 5.5-inch howitzers and for the twin 6-pounder anti-coastal guns which were sent to Peterborough. Breech mechanisms for the 6-pounder tank and anti-tank were turned out at the rate of 100 per week and along with other engineering companies Forgrove made more than 3,000 of these guns in their Leeds factory.

In 1943 they turned to the production of the 20mm Polsen machine gun. This gun had originally been designed in Poland but in 1939 when Poland fell to the Germans it came to the UK. It was similar to the 20mm Oerlikon gun but had less than half the parts and cost less than a quarter of the Oerlikon.

The year 1943 saw the Company amalgamating with Baker Perkins. In 1944 transwrap machines were modified to handle anti-malaria tablets for use by troops in the Far East.

Post-war expansion would be required and an extension was planned to the west of Hartley Property but Hartley had no plans to start production and Forgrove bought the property in 1946. This again doubled the factory production space and it allowed the whole of the pre-war factory to be used as a machine shop.

Following the 1943 merger the Company fortunes continued to improve through the late 1940s and early 1950s and 1950 saw the start of a new works of 40,000 square feet on the Team Valley Trading Estate in Gateshead and Forgrove now employed 700 people between Leeds and Gateshead and to keep pace with the Company growth another factory was opened at Seacroft in Leeds.

In 1961 Baker Perkins acquired Rose Brothers (Gainsborough) Ltd and took the opportunity to group all its packaging machinery assets under one management and on 1 January 1967 Rose Forgrove was formed. Anticipating this amalgamation in 1968 and when it took place in 1969 the Leeds and Seacroft factories were moved into new premises at Seacroft that had been completed by July 1969 and both the Dewsbury Road and the first Seacroft factory freehold properties were sold in 1971. In 1985 Forgrove Machinery became Baker Perkins BCS Ltd and in 1988 it was renamed APV Baker FES Ltd.

In 2025 the buildings have gone through many changes but to see the tragedy they are now especially the frontage on Dewsbury Road is a disgrace to the city, the owners and a complete eyesore to the neighbourhood.

While you’re here, can we ask a favour?

South Leeds Life is published by a not-for-profit social enterprise. We keep our costs as low as possible but we’ve been hit by increases in the print costs for our monthly newspaper which have doubled in the last two years.

Could you help support local community news by making a one off donation, or even better taking out a supporters subscription?

Donate here, or sign up for a subscription at bit.ly/SLLsubscribe

It’s in a very sad state now, it is empty and run down and every one of the windows on this iconic building have been smashed! Reading the history of the building was very interesting