Matthew Murray is believed to have been born in Newcastle-on-Tyne in 1765 but little is known of his early life. His father, when he reached the right age had him apprenticed to a Smith, more probably a Millwright or a Mechanic in his native town. He married a girl, Mary Thompson (1764-1836), from Whickam, County Durham, before his apprenticeship was completed.

He then went to Stockton-on-Tees where he finished his apprenticeship before working as a journeyman mechanic in the flax mill of John Kendrew in Darlington, where the mechanical spinning of flax had been invented. Trade became bad and he heard that there may be a chance of better employment in Leeds so packing a few articles and with his kit of tools he left his wife behind and set out to walk the roughly 60 miles to Leeds.

Arriving, he hadn’t enough money to pay for a bed at the Bay Horse Inn. Telling the landlord that he was hoping to work for John Marshall he was put on trust by him. The morning after his arrival he went to Scotland Mill, a water mill in a picturesque valley at Adel where John Marshall was in the flax manufacturing business. Marshall required assistance and set Murray to work firstly as a handyman doing odd jobs about the machinery. Later, finding his abilities useful, he made him Chief Mechanic and as such he made several suggestions and improvements for which he was given £20.

Murray, now finding his prospects improving sent for his wife and they took a cottage on Black Moor near Adel. Business improved and the old water mill at Adel became too small for all the work. In 1790 Marshall decided to move to larger premises nearer the Leeds manufacturing area and in partnership with a Mr Benyon he started a mill in Holbeck.

The mill was at first driven by a waterwheel the water being supplied by a Savery steam engine and probably from the Hol Beck. It was about this time that Murray took out his first Patent No.1752 of 1790 for ‘A machine for spinning Flax, Cotton, Silk, etc’. In 1793 a Boulton & Watt steam engine of 28hp driving 900 spindles replaced the waterwheel. Murray had charge of this and introduced several minor improvements to this.

In 1793 Murray took out Patent 1971 for ‘Instruments and machines for spinning fibrous materials, etc’, it included a Carding Engine and Spinning Machine. He also introduced ‘Sponge Weights’ and the process of ‘Wet Spinning’ of flax, which created a revolution in the trade.

Murray had been with John Marshall for about 12 years when he was approached to join James Fenton, David Wood, and William Lister to start a works for repairing and making machinery and engines because Leeds at this time had no facilities for doing this.

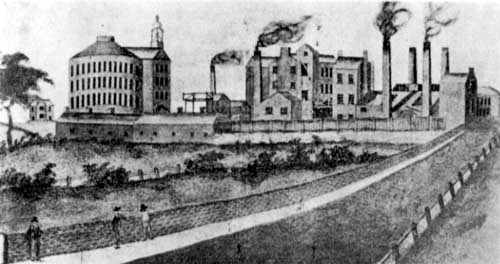

Fenton found most of the capital, Murray was in charge of the engine and building environment, Wood saw to the design of the machinery, while Lister, although his name appeared on contracts, etc appears to have been a sleeping partner. They took the name of Fenton, Murray & Wood. Their first workshop was at Mill Green, Holbeck but this turned out to be too small and they soon moved to a site near Camp Field in Water Lane, Holbeck.

It was here on this new site that he constructed among the other buildings a large circular workshop that was known as the “Round Foundry” and it was here that Murray devoted his energy to making improvements to the steam engine and machine tools.

Murray built himself a house close to the Round Foundry and heated this by a steam system and it was known locally as “Steam Hall”. The house had an exciting episode when a party of Luddites visited the various works with a view to stopping the use of machiner., Murray was not at home but his wife, Mary, refused to talk to the leaders and brought out a pistol and fired, although nobody was hurt they immediately left and caused no more trouble in the area.

Immersing himself in designing more efficient engines and components and taking out Patents on numerous of these, one of these was for parallel motion which depended on the principle that a cycloidal curved formed by one circle rolling in another became a straight line when the diameter of the outer circle was twice that of the inner. Murray passed this to James White who in 1801 was residing in France he submitted it to Napoleon Bonaparte who gave White a medal and this then became White’s Parallel Motion.

It was about 1803 that Murray was seen as a threat to Boulton & Watt who took him to court on charges that he was using their ideas in his engines, the court found against Murray and to try and stop Murray expanding they bought land in Camp Field at the side of Murray’s works. Instead of being discouraged by these rebuffs Murray now devoted more time and energy to the business, orders flowed in and in 1804 he commenced sending work abroad and an engine for Sweden was amongst the first of these foreign orders. During 1807 several large size beam engines were turned out, two going to London water works while others went to various places in the Midlands. Murray brought out his 1809 Flax Heckling machine for which he received the Gold Medal of the Society of Arts and presented to him by the Duke of Sussex.

In 1811 Murray appears to have been working with Trevithick because he produced one of his high-pressure engines which was fitted to a boat in 1812. The vessel in question was originally a French privateer Lugger of 52 feet and propelled by three long sails and 20 oars called the “L’Actif” it was captured and brought to Yarmouth where it was bought by a Quaker, John Wright. It was brought to the Canal Basin in Leeds near Murray’s works and fitted with a steam engine with an eight inch cylinder diameter and a 2 foot 6 inch stroke and a wrought iron boiler with cast iron ends driving paddle wheels. She was renamed “Experiment” and had her first public trial on the River Aire before she went under steam back to Yarmouth where on the 9th August 1813 she made her first public trip with passengers from Bowling Green to Braydon. 1812 was also the year that Murray built engines for John Blenkinsop but this was covered last month in the Blenkinsop article.

In 1813 Murray designed and built some large beam engines, one of which was built and put to work at the Water Hall Mill, Holbeck, where it worked until 1885, a period of 72 years. The years 1815-16 saw Mr Francis B Ogden, United States Vice-Consul in Liverpool, and afterwards engaged in various business projects in America come to England and order from Fenton, Murray & Wood several engines for steam boats, one of which was fitted on board a steam tug on the Mississippi River and it is said to have frequently taken against the stream a ship of 300 to 400 tons on each side and two smaller vessels, Brigs or Schooners towed astern.

Fenton, Murray & Wood were pioneers in the supply of engines, machinery and mill work on the Continent. The Emperor of Russia in recognition of Matthew Murray’s services presented him with a valuable diamond ring and he also received a gold snuff box from the King of Sweden.

He was the first in Leeds to have his works lit with coal gas, and he was largely responsible for getting the authorities to consent to the construction of works for supplying the town with gas. He also acted as a consulting engineer to woollen mills, dye houses, oil mills, and coal mines. Several prominent engineers were trained at the Round Foundry; these were Benjamin Hicks, Charles Todd, David Joy, and Richard Peacock. He earned the right to the title Father of Leeds Engineering.

Matthew Murray died on 20 February 1826 in his 61st year; he was interred in a vault in St. Matthew’s Churchyard, Holbeck where a cast iron obelisk made at the Round Foundry marks his resting place. His wife Mary died in Holbeck in 1836.

Matthew and Mary had four children, three girls and a boy. Margaret born 1786 died 1840 married Richard Jackson; Anne born 1790 died 1874 married Charles Gascoigne Maclea; Matthew born 1793 died 1835, he served his apprenticeship at the Round Foundry then went to Russia where he founded an engineering business in Moscow where he died aged 42; Mary born 1797 died 1864 married Joseph Ogden March (1799-1888).

While you’re here, can we ask a favour?

South Leeds Life is published by a not-for-profit social enterprise. We keep our costs as low as possible but we’ve been hit by increases in the print costs for our monthly newspaper – up 83% in the last 12 months.

Could you help support local community news by making a one off donation, or even better taking out a supporters subscription?

Donate here, or sign up for a subscription at bit.ly/SLLsubscribe

Thank you for taking the time to research and write this very interesting article