John Fowler was born on 11 July 1826 at Melksham, Wiltshire, his father also called John Fowler was a wealthy Quaker merchant who married Rebecca Hull and together they had three daughters and five sons of whom John was the third son.

John Fowler Junior appeared to be a normal but not a clever boy who loved country life and indulged in the usual schoolboy pranks. We are told that he rushed home from school in Corsham to help in the fields at harvest time and an old family friend told how he used to delight in throwing frogs at her during haymaking. When aged ten he became fascinated with the nearby work being carried out by Brunel for the Great Western Railway that connected Bristol and London, the eastern end of Box Tunnel being less than two miles across the fields and which he passed everyday going to and from school.

At the age of 16 he was apprenticed to a corn merchant in Melksham, but he found it dull and monotonous. This situation was probably further aggravated by public opinion against Quaker corn merchants after the Napoleonic Wars ended because people needed someone to blame for the high corn prices. Young John was not very happy and managed to persuade his father to let him go into engineering becoming an apprentice at Gilkes, Wilson & Company in Middlesborough in 1847.

This Company was founded in 1844 by Edgar Gilkes a native of Nailsworth, Gloucestershire and a member of the Society of Friends (Quakers) in partnership with Isaac Wilson of the Kerndal Quaker family. The Company were involved in building steam locomotives and colliery winding engines and they built a number of locomotives for the Stockton & Darlington Railway.

In 1845 Ireland was smitten by a dreaded potato disease which destroyed the staple diet of most of the people and is estimated that over the next four years 1½ million people fled the country or starved to death. The Society of Friends sent a delegation led by Samuel Gurney to Ireland in 1849, John Fowler being one of them and this seems to have set his mind to thinking how his engineering skills could help. Much of the land seemed to have been uncultivated due to poor drainage; this affected Fowler who was convinced there must be a way to bring more of it into production.

The normal way to drain agricultural land was to use a Mole Plough which has a vertical blade with a cylinder or “mole” that is pointed at the front end and as it moves through the soil it leaves an horizontal drainage channel into which porous drainage pipes could be laid, this operation required considerable tractive power and was limited by the strength of the horses that pulled it.

On Fowler’s return to England he worked on the design of a new Mole Plough Engine. His first engine dragged itself across the field on rollers pulling a mole plough as it went; this was driven by a team of horses that walked round a capstan winding in a rope which passed though a pulley that was securely anchored at the far end of the field. The mole would have a string of drainage pipes attached at its rear end and dragged through the channel created by the mole. On completing each length of drains the engine would be turned and the rope let out and the pulley repositioned for the next length.

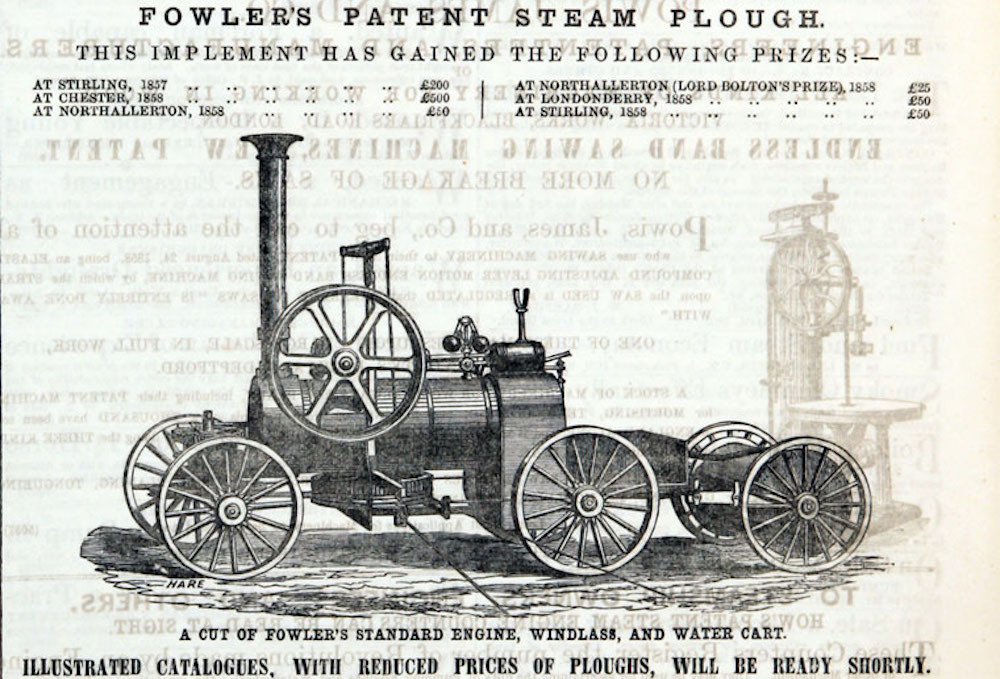

However, Fowler had trouble with the capstan gears and with the rope slipping on the capstan but he was able to demonstrate his Engine at a meeting of the Royal Agricultural Society of England (RASE) at Exeter in 1850 where he laid a drain at a depth of 2 feet 6 inches in heavy clay, for this he was awarded a Silver Medal. The Judges who awarded the medal in their report ascribed the mole plough to Ransome & May, the windlass to a Melksham blacksmith, William Eyres, and the assembly of the unit to Stratton & Company.

John Fowler took a London address and undertook a round of consultations with leading agricultural personalities. One of his first journeys was to Ipswich to the Orwell works of Ransome & May who were well established in the world as the world’s best chilled, cast iron ploughshares. Friendship and co-operation developed between John Fowler and the Ransome Family and especially with William Worby their Works Manager, this was to be a vital factor in the development of the steam plough.

In the early 1850s Fowler formed a partnership with Albert Fry, a member of the Bristol chocolate family and they had both served their apprenticeships together. They acquired the premises and a number of skilled craftsmen from the coach building firm of Stratton Hughes & Company of Templegate, Bristol who had gone into liquidation and they traded as Fowler & Fry until Fowler left in 1856 when it became A & T Fry.

Fowler entered his first steam powered draining plough at Gloucester but it was too heavy to appear. Undeterred he entered it at the RASE Lincoln meeting in 1854 powered by an 8hp portable steam engine supplied by Clayton & Shuttleworth of Lincoln. The cost of the equipment including the engine was £500 and the cost of draining was 35 shillings (£1.75p) per acre. Once again he was awarded a Silver Star.

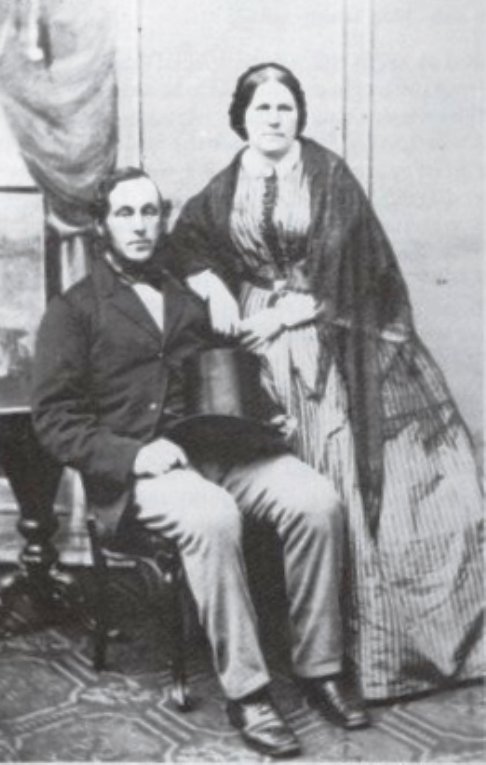

On 30 July 1857 Fowler married his third cousin (once removed), Elizabeth Lucy the fifth child of Joseph Pease, MP for South Durham. Joseph Pease was a wealthy Quaker from Darlington who had supported his father Edward Pease’s proposal for the Stockton & Darlington Railway. Fowler had become closely acquainted with the Pease family while working in Middlesborough. Fowler and his wife settled at Havering in Essex and they had five children, four daughters and a son, John Ernest Fowler.

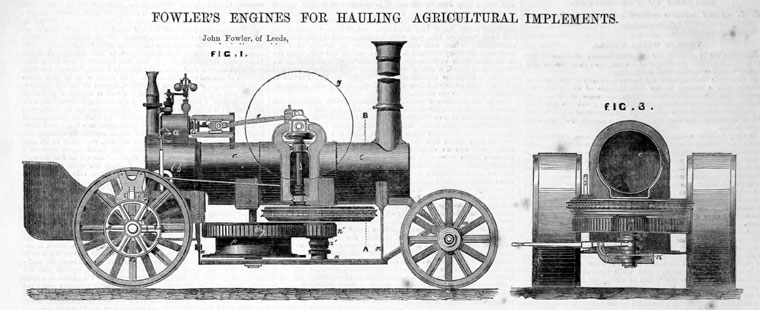

In early 1859 he contacted Leeds locomotive builders Kitson, Thompson & Hewitson at their Airedale Foundry and the outcome was that from 1860 Kitson, Thompson & Hewitson would build a new generation of self-moving ploughing engines for Fowler, based on Clayton & Shuttleworth engines with Stephenson’s ploughing gear, but of much sturdier construction and incorporating the best of current railway locomotive practice.

It was also agreed that Jeremiah Head would be transferred to the Airedale Foundry to supervise manufacture. Robert Stephenson & Company continued to supply Fowler’s windlass and anchor carriage until 1861 and the balance plough and other cultivating equipment continued to be manufactured by Ransomes.

Fowler obtained land at the side of Kitson’s Airedale Foundry and took on a partner, Robert William Eddison in 1860 and the land he acquired was that previously occupied by Wilson, Walker & Company in Leathley Lane, Hunslet, where he built The Steam Plough Works. A Blue Plaque marks the site, now occupied by Costco.

This land was the Spanish leather Works and he leased 727 square yards from Mr Taylor the owner of the works. In 1861 at a Leeds trial of steam ploughing Fowler’s steam cultivator of 12hp ploughed and scarified four acres in four hours, this was made by Kitson & Hewitson while Fowler’s apparatus was manufactured in his own factory in Leeds in connection with Kitson & Hewitson.

In 1862 Fowler formed a partnership with William Watson Hewitson of the above firm and this founded Hewitson & Fowler based at Hunslet. Unfortunately Hewitson died a year later and this led in 1863 to the firm becoming John Fowler & Company. Fowler’s ploughing sets were sold all over the world and were responsible for bringing land into production that previously was uncultivated.

To secure his financial position Fowler formed the Steam Plough Loyalty Company in 1859 in which both friends and relatives subscribed making it one of the earliest Joint Stock Companies; these could be formed under the Companies Act of 1856.

Fowler had worked so hard in developing his ideas that he undermined his health and was advised to take more rest and he retired to Ackworth in Yorkshire to recuperate. Here he was persuaded to take up hunting as a way of getting exercise, while out with the hunt he had a fall and sustained a compound fracture of his arm. While recovering from this mishap he developed tetanus and died at Ackworth on 4 December 1864. His brothers Robert, William, and Barnard had joined him in the business he had founded and they continued to run the Company after his death.

Fowler’s method of ploughing continued to used well into the 20th century when the internal combustion engine allowed the development of light but powerful tractors that could draw a plough behind them.

While you’re here, can we ask a favour?

South Leeds Life is published by a not-for-profit social enterprise. We keep our costs as low as possible but we’ve been hit by increases in the print costs for our monthly newspaper – up 83% in the last 12 months.

Could you help support local community news by making a one off donation, or even better taking out a supporters subscription?

Donate here, or sign up for a subscription at bit.ly/SLLsubscribe

Hello team.

Would you know if it is possible to obtain any more detailed images and or drawings of John Fowlers land ploughs and hauling engines?

Briefly I am aged 80 and semi mobile and have a fascination for steam engines and although I am unable to create physical models I enjoy drawing them in CAD and generating 3D models.

I would appreciate any pointers in the directions of plans etc.

Thank you.